Corrosion free frames for eliminators and louvers for use in Air washers, Humidification plants, Ventilation systems, Air handling units, Cooling towers and such diverse applications to serve Textile, Cement, Power, Coal and many other industries.

All load-bearing M.S. material is completely encased by PVC, thereby avoiding costly surface treatment processes like Hot Dipped Galvanizing. As the existing system of fixing with M.S. angles is maintained, there is no change in the manner in which eliminators and louvers are being installed at present. Design has been modified to discard bolting requirements wherever possible.

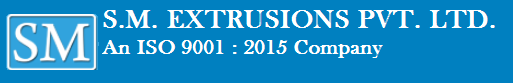

Frames for Eliminators : Wall Mounted

A complete eliminator frame has following configuration:

A pair of stiffeners with spacer bar / notch plate with wall bracket for top (touching the ceiling). These acts like Z- sections used in eliminator frames made of metal. If the ceiling is uneven, the top of stiffener can be filled with cement.

Required pairs of stiffeners with spacer bar / notch plate with wall brackets for middle supports - number of supports is calculated in such a way that there is a horizontal support at not more than 1500 mm of vertical height of eliminator.

A pair of bottom angles (if required by customer) for supporting eliminators at bottom, if there is no continuous support.

Tie bars for all pairs of stiffeners, at approximately 1500 mm of eliminator width. Tie bars have same shape as eliminators.

A pair of side water seals having Z shape. These are to be nailed to side walls outside the eliminators, to prevent escape of water from the sides.

A packing list will give details of all material supplied for the frame.

Frames for Eliminators : Box Typed

A complete box type eliminator frame has following configuration:

A rectangle made of stiffeners with spacer bar for use at top. This will hold eliminators at top and will also form sealing mechanism at top to prevent seepage of water.

A rectangle made of stiffeners with spacer bar for use at bottom. This also provides support to eliminators at bottom.

Required number of additional horizontal supports for holding eliminators at middle. Number of horizontal supports are calculated in such a way that vertical distance between horizontal supports is not more than 1500 mm.

Tie bars for middle pairs of stiffeners, at approximately 1500 mm of eliminator width. Tie bars have same shape as eliminators.

L shaped holdfasts for fixing the box to the wall.

A pair of side water seals having Z shape. These are to be nailed to side walls outside the eliminators, to prevent escape of water from the sides.A packing list will give details of all material supplied for the frame.

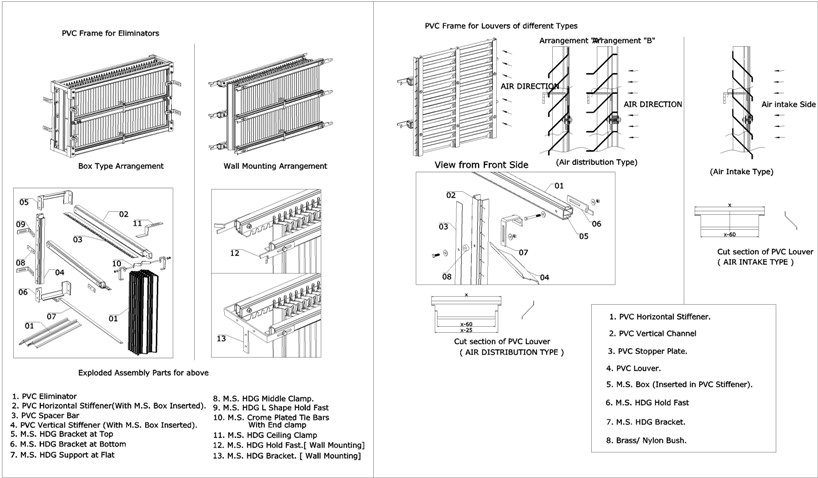

Frames for Louver

A complete louver frame has following configuration:

Required number of horizontal stiffeners for grouting into side walls. There is one horizontal stiffener around 300 mm from the top, one around 300 mm from the bottom and more if required, to maintain a distance of not more than 1300 mm vertically.

Holdfasts and bolts for fixing stiffeners to side walls.

A G channel with slots for louvers for right hand side, a G channel for left hand side and required number of middle G channels, to maintain a distance of not more than 800 mm between two vertical G channels.

Clamps for bolting G channels to horizontal stiffeners with required bolts.

Vertical PVC strips which are bolted to vertical G channels, to act as stoppers, to stop louvers from coming out of slots, once fitted.

We provide a packing list of the components supplied along with distances at which horizontal stiffeners are to be fixed to side walls.

-

- G-Channel – To fix up Louvers Slotting at 60mm / 75mm Pitch of Louver can be attached as per requirements.

-

- Stiffener – With M.S. inserted and sealed at both end Spacer bar with suitable notching as per Eliminator profile.